Product Information Management (PIM) Insights

Troy Sample

Vice President of Sales

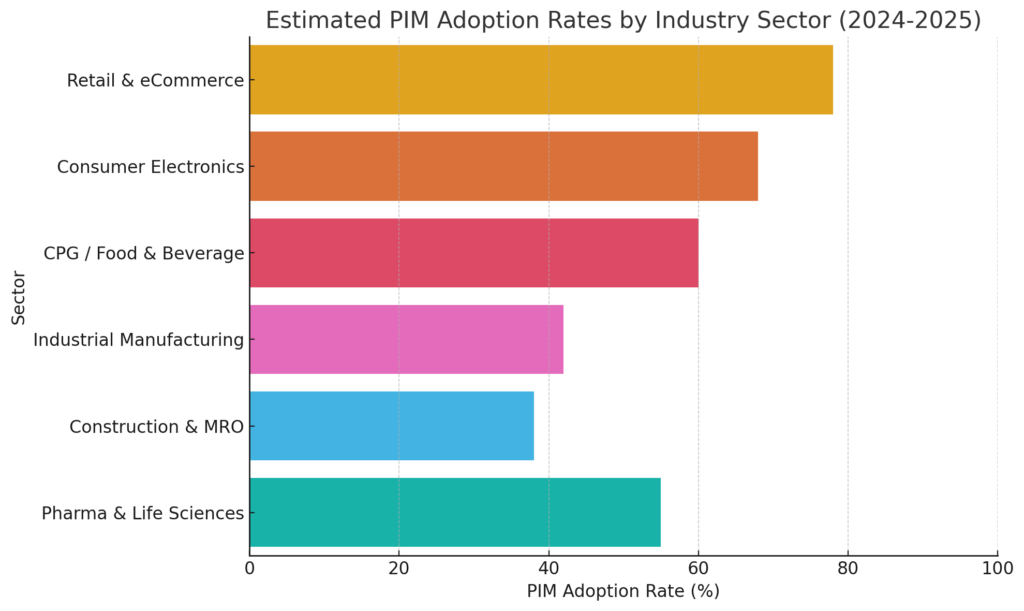

The most impacted segment of the recent trade wars is industrial manufacturing—especially companies importing raw materials like steel, aluminum, and components. Ironically, this is also the sector least likely to have adopted a key tool needed to respond to these disruptions: a Product Information Management (PIM) system.

According to recent industry data (2024–2025), 55–65% of B2B companies globally—particularly mid-sized to large firms—still haven’t implemented a dedicated PIM platform. Adoption rates vary significantly by industry, and industrial manufacturing, construction, and MRO lag behind, with adoption hovering between 35% and 50%.

One industrial marketing executive quipped:

“It would be faster to train penguins in the McDonald Islands to manufacture their products than it would be to communicate a country of origin change to the market.”

They’re not far off.

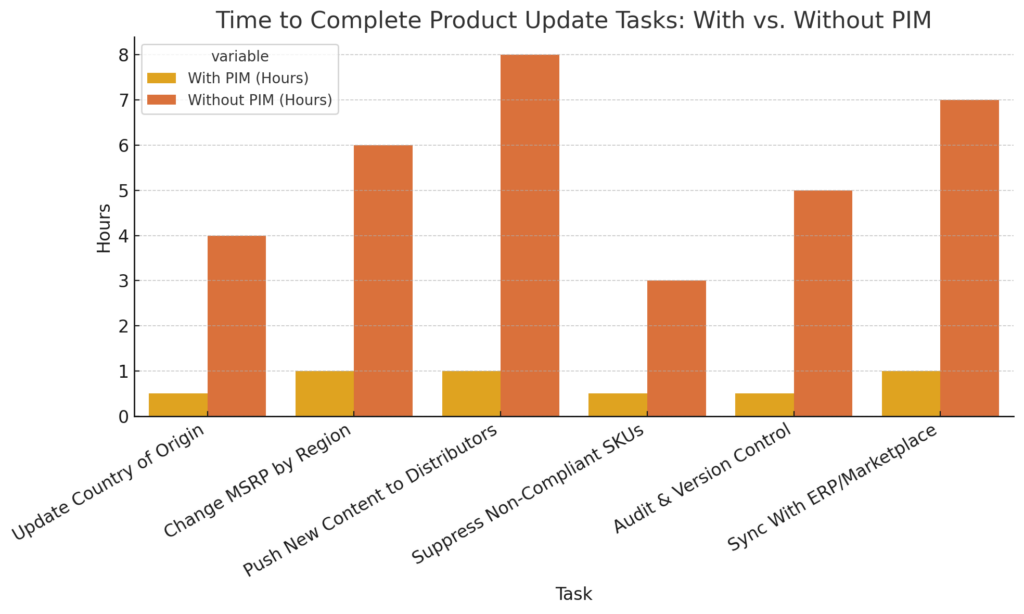

Updating country of origin (COO) data without a PIM takes, on average, 4 hours. With a PIM? Just 30 minutes. Publishing those changes to distributors can take 8+ hours with spreadsheets—versus 1 hour with a modern PIM.

What Did We Learn from COVID?

During the early stages of the pandemic, we saw a spike in investment in digital tools that enabled companies to pivot quickly. But post-COVID, that momentum slowed. Companies that did invest in modern systems are better positioned today to adapt to this next wave of global business disruption.

Why Industrial Manufacturers Still Lag Behind

- Legacy Systems: Many still rely on ERP, Excel, or custom-built tools.

- Complex BOMs & Variants: These are difficult to model in simple platforms.

- Distributor-Led Sales: Many defer product data management to channel partners like Grainger, AD, or MSC.

- Underinvestment in Digital: Marketing and product teams often lack modern tools and processes.

The Risks of Relying on Primitive Tools

Companies still managing product data manually face:

- Inability to quickly pivot product content (e.g., COO updates).

- Manual errors in MSRP changes, spec sheets, and compliance documentation.

- Delayed syndication to platforms like Grainger, Amazon Business, and eProcurement portals.

- Missed revenue during distributor promotions or when sourcing needs shift.

Bottom Line: It’s Time to Modernize

Regardless of your industry, it’s time to reevaluate your tools and processes to prepare for today’s volatility—and what’s coming next.

For industrial manufacturers specifically:

- Nearly half still lack a PIM.

- They face greater risk when pricing, sourcing, or compliance needs to change quickly.

- PIM adoption is accelerating as supply chains digitize and trade complexity increases.

If you’re still managing product content with spreadsheets, now is the time to invest in a foundation that can adapt with your business—before the next disruption hits.